EIES rate controller GUARDIAN®

Guardian® rate controller

There are always cases when the Quartz crystal measurement technology reaches its limits. The reasons are usually very high or very low rates or a very long process duration. In inline coating plants, even high rates may be associated with long process durations or long plant opening intervals. In such cases, Quartz crystals are not suitable for rate measurement, either because they are not sensitive enough or because their service life is too short.

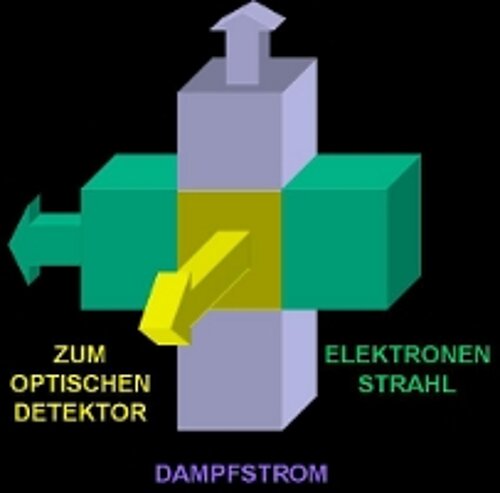

The EIES measuring method used in the Guardian® does not require a measuring element that is consumed during the process. In the sensor, which is located in the vapor stream, a part of this vapor is electronically excited and then emits lines characteristic of the elements contained in the vapor (Electron Impact Emission Spectroscopy). A suitable line of the relevant element is filtered out of this light and converted into an electrical signal by means of a photomultiplier (PMT). Since the intensity of the emitted light is proportional to the vapor density or evaporation rate, this also applies to the PMT signal. In principle, the EIES sensor has an unlimited lifetime. In reality, of course, there are limits, mainly the lifetime of the heating coil used for excitation and, at extremely high occupancy, a closing of the window.

Advantages of the EIES measuring method

-

large dynamic range, i.e. measurement of very small and very large rates

element-specific measurement, therefore also applicable for vapor mixtures

very long sensor lifetime

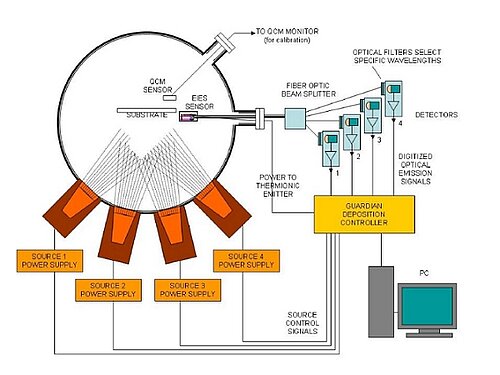

EIES sensors are fully UHV compatibleAn EIES measuring branch consists of the sensor with feedthrough, the photomultiplier and the Guardian® instrument. This device calculates rate and coating thickness and controls the coating sources. Since it does not have its own display, the display and processing of the data requires a PC on which the supplied software is installed.

The light coming from the EIES sensor can be split into up to 4 partial beams. Each of these partial beams can be used to control a coating source using its own PMT line filter combination. The 4 control channels of the smaller Guardian® control unit can be operated completely independently. The larger Guardian® control unit has two EIES channels and up to 8 control channels for source control. As simple as the Guardian® and the EIES principle may seem at first glance, practical use must always be well prepared. This starts with the positioning and orientation of the EIES sensor. But also the selection of suitable emission lines and the evaluation of the process conditions under which the sensor is to be used can turn out to be quite critical points.

Therefore, a detailed preparatory discussion should always take place before the decision for the Guardian® is made, preferably at the vacuum plant in question.

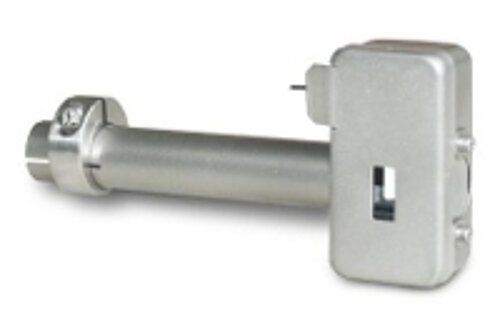

EIES sensor

In addition to the EIES standard sensor shown here, there is a dual sensor, which can be used to eliminate signal disturbances by an excessive gas background in the coating chamber.